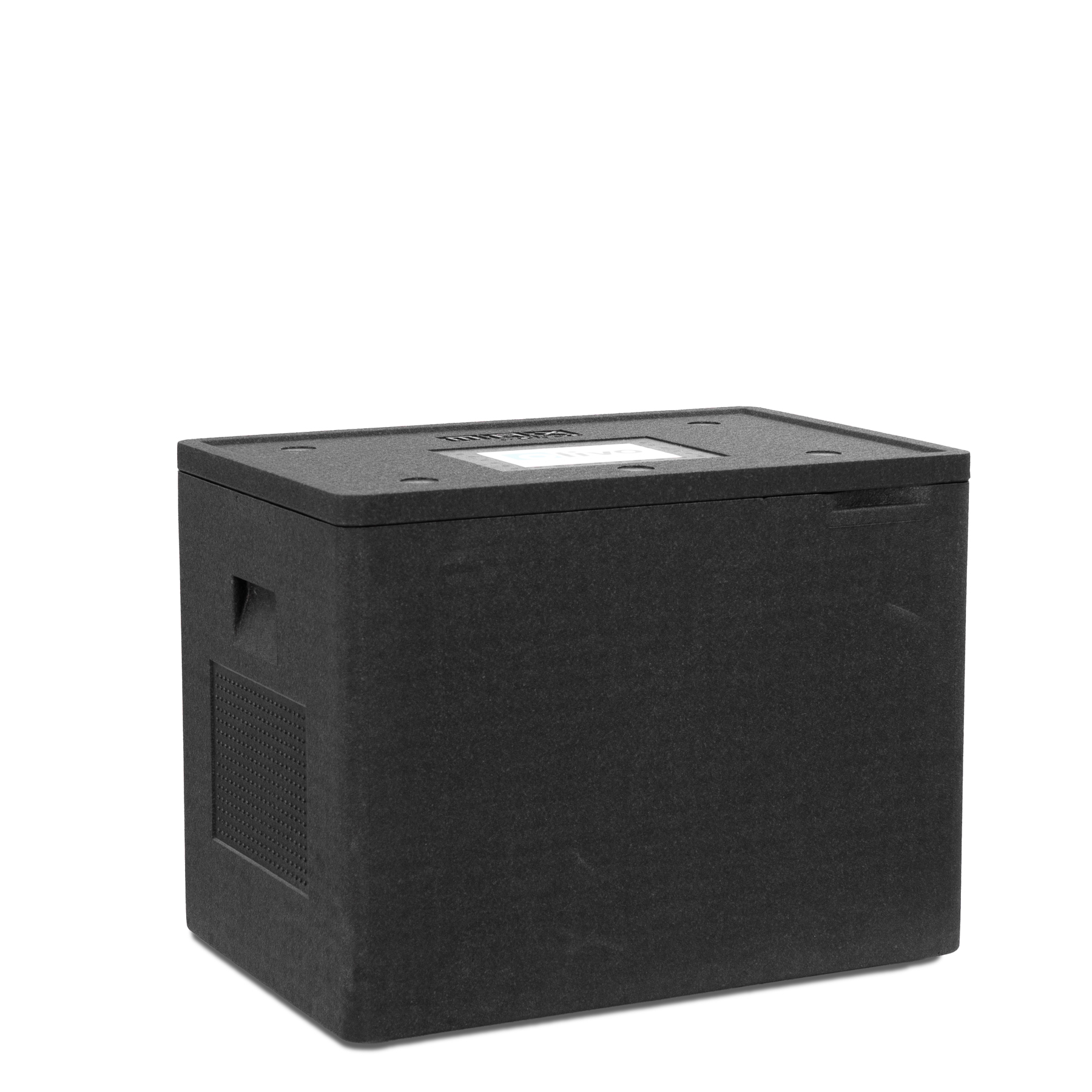

Ext. dim. : 595 x 395 x 455 mm,

Volume : 60 L,

Cold source : eutectic plate TOP 64,

Logistics format : Quarter Euro-pallet 800 x 1200

View detailsPlaque eutectique

The preparation of the eutectic plate varies according to the holding temperature required and the area of application.

A eutectic plate in its solid state is capable of absorbing energy: it heats up until it becomes completely liquid.

A eutectic plate in its liquid state is able to give up energy: it cools until it becomes completely solid.

To solidify the eutectic plate :

The solidification of the eutectic solution must take place in an environment where the temperature is 5°C below the melting temperature of the plate. The duration of this phase change, from liquid to solid, depends on the energy input. Nevertheless, we recommend immobilisation in a cold chamber for 24 hours. However, the chamber must meet two fundamental criteria: it must be sufficiently powerful and ventilated to allow the free circulation of cold air around the faces of the eutectic plate. The use of a freezing rack optimises the preparation phase. An air gap of 2cm around the sides of the TOPs encourages convection and therefore the solidification of the plates.

=> How do I know if my eutectic sheet is ready for use?

A eutectic plate that is ready for use, i.e. 100% loaded, must be 100% solid if the outside temperature is higher than the temperature of the products being transported.

Without this sine qua none condition, we cannot guarantee that the temperature of the products transported will be maintained. To achieve this, it is necessary to comply with the eutectic plate preparation protocol: 24 hours of preparation in an enclosure where the temperature is at least 5°C below the melting temperature of the eutectic plate. The method of storing the plates during the loading phase is also decisive: 2cm of space between each plate to create corridors for the circulation of cold air.

For more details, please download the document on the use of eutectic sheets.

To maximise cold diffusion in the isothermal enclosure, the eutectic plates should be placed in the appropriate positions.

As a reminder, cold spreads from top to bottom.

The isothermal containers are fitted with rotomoulded guides on which the sheets can be positioned directly or which allow a sheet-holder grid to slide over them.

To avoid damaging your fresh produce through direct contact with the cold source, we recommend that you leave 5 cm between the plate and the produce.

Containers and accessories compatible with this product

Isothermal containers

Can eutectic plates be stacked in a BOX ?

It is not recommended that you place eutectic plates one on top of the other. The purpose of a eutectic plate is to diffuse cold. And that diffusion will not be optimal if the plates are stacked. Each BOX is designed with a specific space for the eutectic plate. This can be a net under the lid or moulded-in slots. These locations are chosen to optimise the diffusion of the cold by creating convection channels that allow the cold air to circulate evenly.

Eutectic plates

How does a eutectic plate work ?

A eutectic plate is a device designed to store thermal energy, in the form of heat or cold, and then to release it gradually to maintain a specific temperature. It works on the thermodynamic principle of phase change, i.e. the transformation of a solution from liquid to solid state and vice versa.

The eutectic plate absorbs the heat from outside the container while releasing a constant amount of cold. It is by passing from the solid to the liquid state, by the absorption-release phenomenon, that the eutectic plate maintains a constant temperature inside the insulated container.

Eutectic plates

What are the parameters that guarantee the effectiveness of a eutectic plate ?

How effective a eutectic plate is depends on several parameters, namely:

Latent heat of fusion according to melting temperature in Joules

| +21°C | 122 KJoules |

| 0°C | 251 KJoules |

| -3°C | 258 KJoules |

| -12°C | 451 KJoules |

| -17°C | 409 KJoules |

| -21°C | 239 KJoules |