Insulated container supplier or partner in your cold chain logistics ?

26 February 2026 by Edina GÁLFI

16 July 2025 by Edina GÁLFI

The transportation of frozen products is a key link in the cold chain. It addresses critical sanitary, economic, and logistical challenges—especially in the agri-food, retail, and healthcare sectors. A single temperature deviation can degrade product quality or render it unfit for consumption.

So how can we ensure the safe, compliant, and efficient transport of frozen goods? What standards must be met, what equipment is required, and what are the best-suited logistics solutions? Here’s what you need to know.

Frozen product transport is governed by strict requirements to preserve the microbiological, nutritional, and organoleptic integrity of goods. The goal: maintain a consistent temperature and avoid any break in the cold chain.

To ensure compliance, it’s essential to:

Two main technologies are used to maintain cold temperatures:

The choice of technology depends on:

Poor control of these factors can lead to product loss, reduced perceived quality, or even endanger the consumer.

The regulatory temperature for transporting frozen goods is –18°C or lower. A temporary tolerance of up to –15°C is allowed during logistical operations (e.g., loading and unloading), provided that the average temperature remains compliant throughout the entire transport.

Any prolonged temperature rise above –15°C constitutes a cold chain breach and can lead to:

To prevent these risks, temperature traceability tools are now essential: sensors, connected data loggers, IoT devices, automatic alerts…

Connected solutions offer real-time monitoring and rapid response in the event of a temperature deviation. They can also serve as proof of compliance during inspections or disputes.

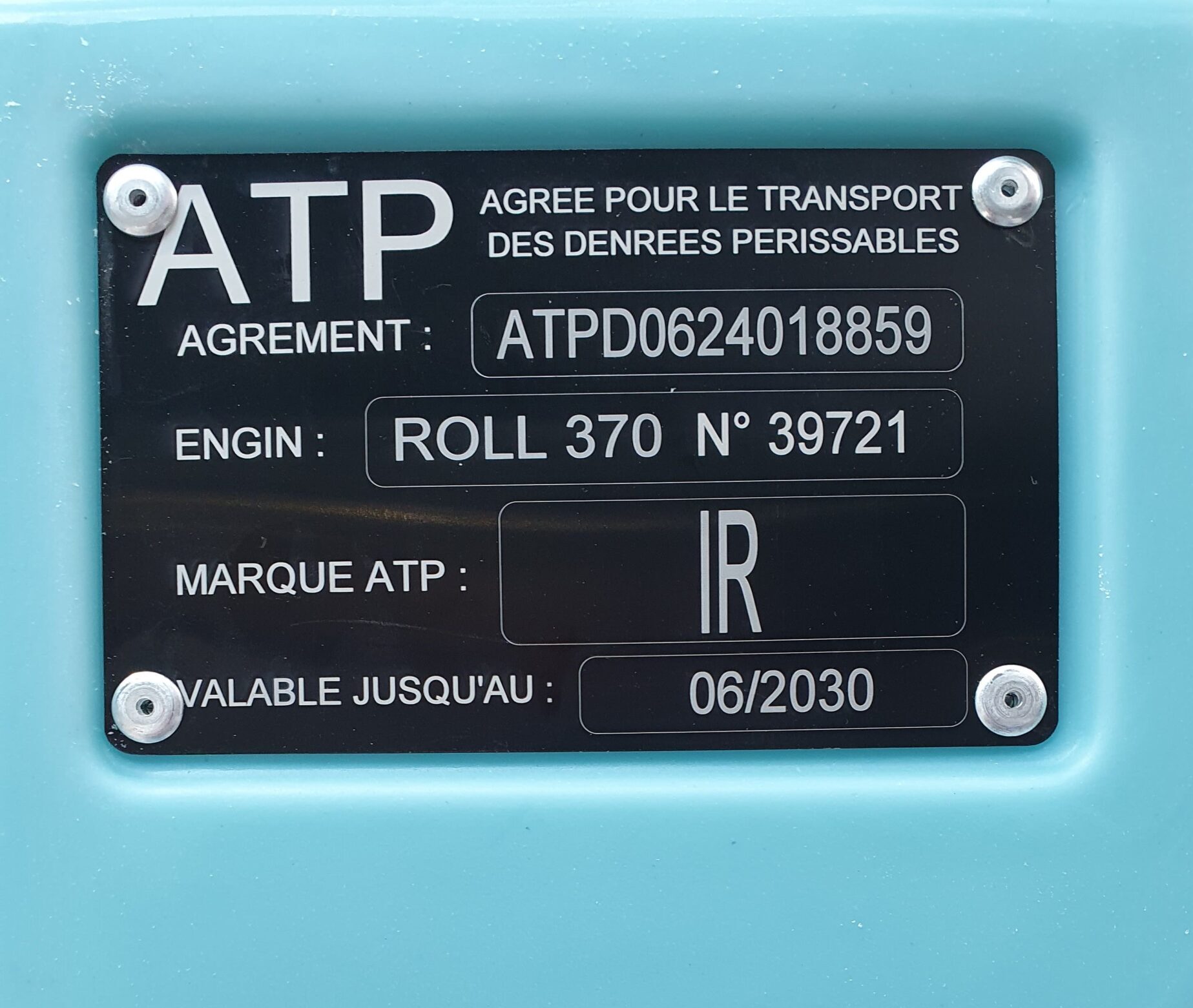

The ATP Agreement (Agreement on the International Carriage of Perishable Foodstuffs)

ATP is an international agreement governing the road transport of perishable goods between signatory countries. It requires :

A vehicle or container that complies with ATP displays a specific marking on the body, indicating the type of insulation and refrigeration category.

In France, national laws complement ATP through various texts:

Responsibility is shared across the entire chain: producers, logistics providers, distributors, as well as foodservice operators and healthcare facilities.

Compliance with standards is not just an obligation—it’s a competitive advantage and a sign of reliability for customers and partners.

1. Refrigerated trucks: the go-to for bulk transport

Refrigerated vehicles are equipped with mechanical cooling systems that maintain a constant temperature over long distances. They’re ideal for:

However, their logistical rigidity (vehicle size, energy consumption, costs) can limit their use for:

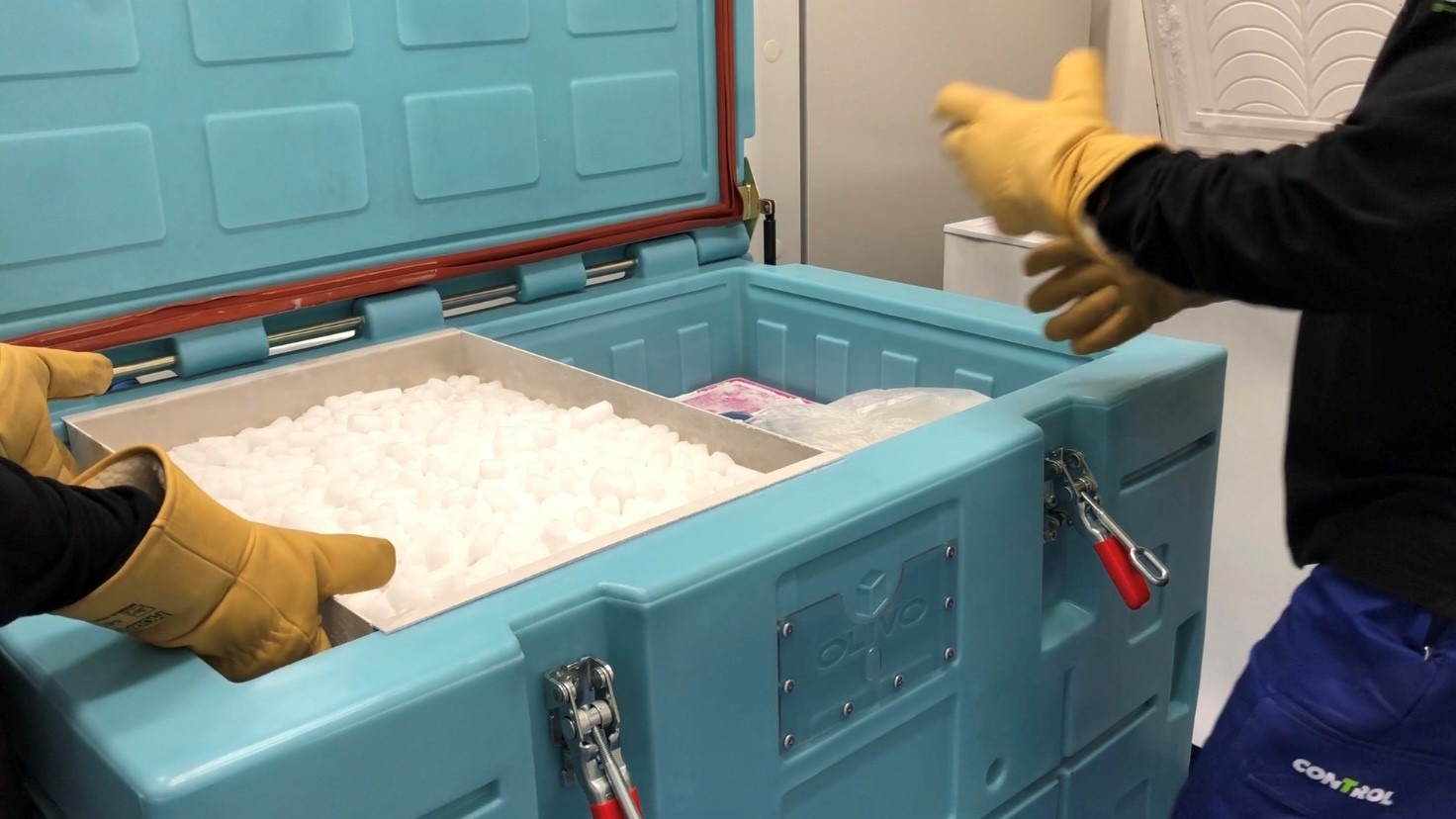

2. Olivo insulated containers: a flexible and autonomous solution

Olivo insulated containers, used with –21°C cold accumulators or cryogenic cooling, meet both flexibility and performance demands. They allow:

They are available in various formats: roll containers, bins, boxes—with or without wheels, pallet-mounted, with ergonomic handles… Each solution is tailored to your business needs.

Frozen transport is a strategic part of the value chain. Perfect cold chain management allows companies to:

Olivo supports professionals in the agri-food industry, institutional catering, retail, as well as healthcare and pharmaceutical sectors, with robust, tailored, and scalable cold chain solutions.

Safely transporting frozen goods depends on three key pillars:

Whether you use refrigerated trucks or autonomous insulated containers, every link in your cold chain must be optimized and traceable.

With Olivo, you benefit from: