Ext. dim. : 800 x 1200 x 1270 mm,

Volume : 516 L,

Cold source : eutectic plate TOP 900,

Logistics format : Euro-pallet 800 x 1200

View detailsOlivo products are 100% made in France

31 results

Ext. dim. : 800 x 1200 x 1270 mm,

Volume : 516 L,

Cold source : eutectic plate TOP 900,

Logistics format : Euro-pallet 800 x 1200

View details

Ext. dim. : 600 x 715 x 800 mm,

Volume : 138 L,

Cold source : eutectic plate TOP 130,

Compatible format : Roll cage,

View details

Ext. dim. : 600 x 800 x 1125 mm,

Volume : 215 L,

Cold sources : eutectic plate TOP 370 et SiberSnow ®,

Logistics formats : Euronorm crate 600 x 400 et Half Euro-pallet 80 x 600

View details

Ext. dim. : 600 x 800 x 1130 mm,

Volume : 215 L,

Cold source : eutectic plate TOP 370,

Logistics formats : Euronorm trays, Gastronorm trays et Half Euro-pallet 80 x 600

View details

Ext. dim. : 695 x 805 x 1135 mm,

Volume : 299 L,

Cold sources : eutectic plate TOP 580 et SiberSnow ®,

Logistics format : Roll cage

View details

Ext. dim. : 600 x 800 x 1670 mm,

Volume : 364 L,

Cold sources : eutectic plate TOP 370 et SiberSnow ®,

Logistics formats : Euronorm crate 600 x 400 et Half Euro-pallet 80 x 600

View details

Ext. dim. : 600 x 800 x 1670 mm,

Volume : 364 L,

Cold source : eutectic plate TOP 370,

Logistics formats : Euronorm trays, Gastronorm trays et Half Euro-pallet 80 x 600

View details

Ext. dim. : 715 x 850 x 1700 mm,

Volume : 500 L,

Cold sources : eutectic plate TOP 370 et SiberSnow ®,

Logistics format : Roll cage

View details

Ext. dim. : 660 x 950 x 1855 mm,

Volume : 550 L,

Cold source : eutectic plate TOP 370,

Logistics format : Roll cage

View details

Ext. dim. : 810 x 715 x 1900 mm,

Volume : 563 L,

Cold sources : eutectic plate TOP 580 et SiberSnow ®,

Logistics format : Roll cage

View details

Ext. dim. : 740 x 940 x 1840 mm,

Volume : 644 L,

Cold source : eutectic plate TOP 900,

Logistics format : Roll cage

View details

Ext. dim. : 800 x 1030 x 1720 mm,

Volume : 675 L,

Cold source : eutectic plate TOP 780,

View details

Ext. dim. : 800 x 1000 x 1900 mm,

Volume : 750 L,

Cold sources : eutectic plate TOP 780 et SiberSnow ®,

Logistics format : Euronorm crate 600 x 400

View details

Ext. dim. : 800 x 1000 x 1900 mm,

Volume : 710 L,

Cold source : eutectic plate TOP 780,

Logistics format : Euronorm crate 600 x 400

View details

Ext. dim. : 800 x 1200 x 1860 mm,

Volume : 885 L,

Cold sources : eutectic plate TOP 900 et SiberSnow ®,

Logistics format : Euro-pallet 800 x 1200

View details

Ext. dim. : 800 x 1200 x 1860 mm,

Volume : 840 L,

Cold source : eutectic plate TOP 900,

Logistics format : Euro-pallet 800 x 1200

View details

Ext. dim. : 1000 x 1200 x 1690 mm,

Volume : 1092 L,

Cold sources : eutectic plate TOP 370 et SiberSnow ®,

Logistics format : ISO Pallet 1000 x 1200

View details

Ext. dim. : 1000 x 1200 x 1690 mm,

Volume : 1022 L,

Cold source : eutectic plate TOP 370,

Logistics format : ISO Pallet 1000 x 1200

View details

Ext. dim. : 1100 x 1100 x 1930 mm,

Volume : 1285 L,

Cold source : eutectic plate TOP 370,

Logistics format : Asia pallet 1100 x 1100

View details

Ext. dim. : 1000 x 1200 x 2000 mm,

Volume : 1420 L,

Cold sources : eutectic plate TOP 370 et SiberSnow ®,

Logistics format : ISO Pallet 1000 x 1200

View details

Ext. dim. : 1000 x 1200 x 2000 mm,

Volume : 1285 L,

Cold source : eutectic plate TOP 370,

Logistics format : ISO Pallet 1000 x 1200

View details

Ext. dim. : 490 x 510 x 663 mm,

Volume : 26 L,

Cold source : eutectic plate TOP 25,

View details

Ext. dim. : 600 x 500 x 580 mm,

Volume : 53 L,

Cold source : eutectic plate TOP 55,

Logistics format : Quarter ISO Pallet 1000 x 1200

View details

Ext. dim. : 680 x 560 x 850 mm,

Volume : 105 L,

Cold source : eutectic plate TOP 70,

View details

Ext. dim. : 800 x 600 x 715 mm,

Volume : 132 L,

Cold source : eutectic plate TOP 130,

Logistics formats : Euronorm crate 600 x 400 et Half Euro-pallet 80 x 600

View details

Ext. dim. : 800 x 600 x 1050 mm,

Volume : 159 L,

Cold source : eutectic plate TOP 370,

Logistics format : Half Euro-pallet 80 x 600

View details

Ext. dim. : 1200 x 800 x 965 mm,

Volume : 327 L,

Cold source : eutectic plate TOP 370,

Logistics format : Euro-pallet 800 x 1200

View details

Ext. dim. : 1200 x 800 x 1085 mm,

Volume : 417 L,

Cold source : eutectic plate TOP 900,

Logistics format : Euro-pallet 800 x 1200

View details

Ext. dim. : 1200 x 800 x 1085 mm,

Volume : 417 L,

Logistics format : Euro-pallet 800 x 1200

View details

Ext. dim. : 595 x 395 x 455 mm,

Volume : 60 L,

Cold source : eutectic plate TOP 64,

Logistics format : Quarter Euro-pallet 800 x 1200

View details

Ext. dim. : 555 x 360 x 331 mm,

Volume : 34 L,

Cold sources : eutectic plate TOP 64 et SiberCity®,

View detailsDo you need more information or would you like to talk to our teams about servicing and maintaining your fleet of insulated containers?

ZA Charles Chana

1 boulevard des Mineurs – CS 50019

42230 Roche-la-Molière

Tel : +33 (0)4 77 90 68 63

| Product name | External dimensions | Weight with cold source | Interior volume | K coefficient | Logistics format |

|---|---|---|---|---|---|

| Container BAC25 – EUTECTIC PLATE TOP25 | 490x510x663 mm | 18.6 kg | 26 L | ||

| Container BAC55 – EUTECTIC PLATE TOP55 | 600x500x580 mm | 18.75 kg | 53 L | 0.39W/m2.K | |

| Container BAC55 – DRY ICE DRAWER | 600x500x580 mm | 53 L | 0.39W/m2.K | ||

| Container BAC70 – EUTECTIC PLATE TOP70 | 680x560x850 mm | 37.9 kg | 105 L | 0.40W/m2.K | |

| Container BAC70 – DRY ICE DRAWER | 680x560x850 mm | 105 L | 0.40W/m2.K | ||

| Container BAC130 – EUTECTIC PLATE TOP130 | 800x600x715 mm | 36.3 kg | 132 L | 0.36W/m2.K | Half pallet Europe | Euronorme |

| Container BAC130 – DRY ICE DRAWER | 800x600x715 mm | 132 L | 0.36W/m2.K | Half pallet Europe | Euronorme | |

| Container BAC160 – EUTECTIC PLATE TOP370 | 800x600x1050 mm | 41.8 kg | 159 L | 0.32W/m2.K | Half pallet Europe | Euronorme |

| Container BAC320 – EUTECTIC PLATE TOP370 | 1200x800x965 mm | 97.9 kg | 327 L | 0.35W/m2.K | Palette Europe |

| Container BAC420 – EUTECTIC PLATE TOP900 | 1200x800x1085 mm | 106.9 kg | 420 L | 0.33W/m2.K | Palette Europe |

| Container BAC420 – DRY ICE DRAWER | 1200x800x1085 mm | Palette Europe |

The thermal shipping container is a multi-purpose transport box with insulating walls and door (or lid).

The thermal insulation of the isothermal container’s walls functions to reduce thermal exchanges between the inside and outside of the box.

The isothermal quality of an insulated container is assessed by the value of its heat exchange coefficient, known as the K coefficient. The K coefficient represents the overall heat loss of the isothermal container.

A low K coefficient value indicates a better isothermal quality of the isothermal box than a higher K value. For example, an insulated box with a K coefficient of 0.40 W/m2.K performs better than one with a K coefficient of 0.70 W/m2.K.

To compare insulated boxes, it’s important to know the value of their respective K coefficients. This technical data is crucial for estimating the optimization of cold logistics in a professional setting.

Remember that the level of thermal insulation affects the duration of temperature maintenance and directly influences the amount of cold required. Visually assessing the insulation quality of a container is impossible. It is also not feasible to approximate the value through calculations based on material conductivities. The insulation value is measured during a technical test conducted by an accredited laboratory.

While isotherm protects the load from overheating, adding cold to the inside of the isothermal box/container both maintains the temperature stable and increases the length of time the temperature is maintained.

By adding cold to the inside of a refrigerated cabinet, you can maintain the inside temperature for a longer period of time, in line with your transport time. The choice of refrigeration for the container is vital, as the cold supply plays a direct part in ensuring that the temperature is maintained correctly.

When the isothermal cold container is fitted with a non-mechanical cooling system, it is referred to as a refrigerated container or refrigerated container.

Several types of cold are possible in a refrigerated container. Olivo isothermal containers are not refrigerated containers fitted with a mechanical unit. Olivo essentially offers mobile refrigeration that operates autonomously.

The refrigerated isothermal container is therefore designed for transport and more specifically for the final distribution phase. Because it is self-contained and requires no external energy to operate and maintain temperature, the flat pack insulated containers is highly flexible in use in a logistics circuit.

The cold isothermal container is the champion of the right temperature, in all conditions.

The refrigerated container can wait for hours in any situation, with no risk of the cold breaking down :

Whatever the hazards of a distribution round, traffic jams, repeated opening of vehicle doors, recipients waiting to unload, your products can be transported under thermal protection without breakage with insulated storage units.

The Agreement on the Transport of Perishable Foodstuffs – ATP – concerns the international transport of foodstuffs and defines the means to be used for such transport. The ATP is a United Nations agreement signed by almost 50 countries, which sets out the requirements for temperature-controlled transport (refrigerated transport).

The ATP lays down the rules for international transport, but these rules are also widely recognised for national transport. This is the case in France, which applies the ATP for cold transport on its territory to all brands.

As Olivo is a French manufacturer, all its food containers have complied with the technical requirements of the ATP since the 1980s. Olivo’s production is ATP-certified in compliance with the standards.

The ATP text can be downloaded from the UNECE website.

Your country may not require professional containers to comply with the ATP qualification. In this case, ATP quality is not an obligation but a choice: it guarantees the technical quality of the isothermal container and the efficiency of the associated refrigeration system.

Using a professional container is fully in line with the circular economy approach, which aims to limit the consumption and waste of resources while providing a quality service.

With excellent temperature maintenance, the methods used are simple and non-polluting :

The isothermal container combines efficiency and simplicity to meet the ever more demanding requirements of modern logistics in terms of cost, quality, safety and responsiveness. In a way, this is the paradox of the isothermal container: such a simple solution for increasingly complex logistics.

All the materials used for the walls of insulated containers are compatible with food contact, in particular the use of GN1/3 Gastronorm eutectic plate.

ROLL and BAC food containers are mainly made of polyethylene. Rotational moulding technology is used to create one-piece, double-walled moulded parts. The insulation is then injected in-situ. The monobloc design gives Olivo containers excellent resistance to impact during handling, and a longer lifespan. The monobloc technique has resulted in a drastic reduction in maintenance for the isothermal container and the integrity of the isothermal value without any noticeable deterioration.

The white BAC insulated containers have a more traditional design and are made from a fibreglass/polyester composite. Olivo polyester containers are designed for very low temperatures of around -80°C. Users of polyester insulated containers come from the dry ice industry. Dry ice manufacturers use polyester insulated containers to store and deliver dry ice.

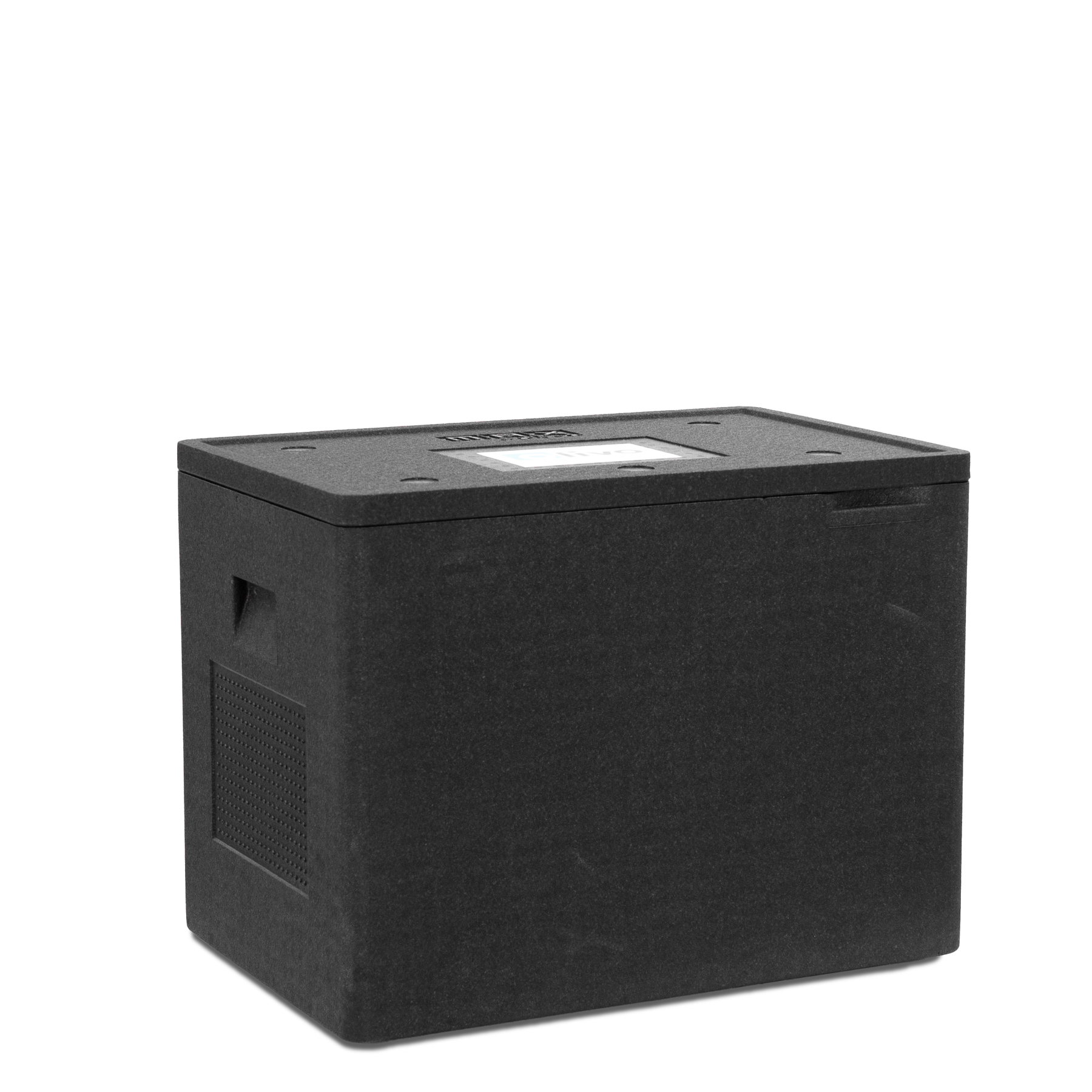

The isothermal boxes in the BOX range are moulded from expanded polypropylene (EPP). PPE is a black material that is both resistant and isothermal (secure storage units strong), yet light as a feather. Even if these materials look similar, don’t confuse PPE with polystyrene (PSE). PPE is a noble material that is much more resistant than polystyrene. Olivo has chosen to mould EPP in a high density for good resistance. BOX insulated boxes are ideal for last-mile logistics and home delivery.

Over the years, Olivo has given priority to recyclable construction materials. This is the case for rotomoulded polyethylene and PPE. Since 2008, Olivo has been offering a container end-of-life treatment service: dismantling services for components and materials entrusted to recycling channels.

Olivo has selected the best-performing insulating materials so that its insulated containers of all categories can benefit from a very good K coefficient value, whatever the size of the storage container.

For ROLL and BAC containers, expanded polyurethane foam uses latest-generation foaming agents to provide better insulation. The polyurethane insulating material is injected in-situ, without thermal bridges or assembly. Transportable Extremely versatile.

BOXes are made from a single material: expanded polypropylene. EPP is an insulating material that also ensures the structural strength of the packaging. One of the advantages of PPE as an insulator is that it can be recycled. The single-material design of BOX packaging also aims to facilitate end-of-life recycling of our products. Prices (excl. or incl. VAT) on request.