3 good practices in the transport of chilled goods

14 February 2024 by Edina GÁLFI

2 December 2022 by Edina GÁLFI

Transporting fruits and vegetables (F&V) represents a real logistics challenge. In fact the differences in their composition and in their origin and harvesting generate diverse and varied needs as regards keeping them cool. Different properties and origins determine the factors that will influence the ripening of fruit and vegetables: humidity rate, storage temperature, amount of light they are exposed to, etc.

It is worth remembering that failures to maintain the cold chain lead to 13% of the world’s food production being wasted every year.

Families of fruits: tropical and exotic fruits | wild fruits | pome fruits | stone fruits | nuts | citrus fruits | red fruits

Families of vegetables: exotic vegetables | pulses and seeds | leafy vegetables | root, tuber and stem vegetables | mushrooms | brassicas | fresh herbs | lettuces

Then there is a difficult-to categorise family of fruits that are considered as vegetables. This includes the tomato, the cucumber and the water melon.

Exposing F&Vs to an appropriate cold chain slows and limits ripening. And that preserves their visual and gustatory quality. And ensures they are fit for sale and consumption.

External factors that have an impact:

Two physiological characteristics of F&Vs explain the need for rigorous cold chain logistics: water and ethylene. As they are made up of 80 to 95% water, fruit and vegetables “perspire”. This phenomenon therefore causes the product to dehydrate and lose weight and even shrivel, modifying the texture and visual appearance.

In fact, F&Vs continue to ripen after they are harvested. As living material, they never stop gaseous exchanges with the environment. Softening of the flesh and changes in colour are therefore evidence of the continuing changes in F&Vs after they are harvested.

Focus on climacteric respiration

The phenomenon of climacteric respiration is a process of emitting ethylene which is correlated with a fruit or vegetable’s respiration rate. It corresponds to a quantity of carbon dioxide given off by a plant. This level of respiration is closely linked to the temperature to which the product is exposed. The higher the temperature, the greater the increase in the respiration rate. Finally, the lower the temperature, the slower the climacteric respiration rate.

It is also interesting to look at the respiration quotient of transported F&Vs. This is determined by the ratio of the volume of carbon dioxide produced by the F&V to the volume of oxygen absorbed during the same period.

The higher the fruit or vegetable’s respiration rate, the shorter its shelf life.

To conclude, when a fruit or vegetable continues to ripen after harvesting, it is referred to as climacteric. Examples include tomatoes, avocados, peaches, apples and bananas. On the other hand, a fruit that stops ripening when it is harvested is known as non-climacteric. Examples include pineapples, oranges, grapes and cherries.

It should be noted that any fruit or vegetable placed in contact with a climacteric fruit or vegetable will see its ripening process accelerated. A factor, therefore, to be taken into consideration when packing and transporting your fruit and vegetables.

As already stated, there are several types of factors that can impact the premature aging of F&Vs.

Temperature: submitting a fruit or vegetable to a thermal shock can be fatal to it. A thermal shock can cause condensation on the surface of a fruit or vegetable and, in some cases, the development of rot.

A low temperature can slow the metabolism of F&Vs. However, you must be careful not to overexpose them. For temperatures that are too low can have the opposite effect: blackening of the flesh, dulling of the aromas, etc. These symptoms are referred to as “chilling injury”.

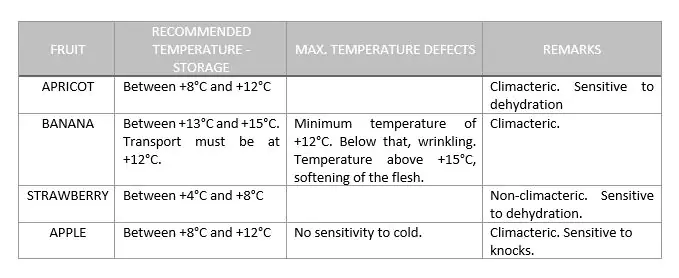

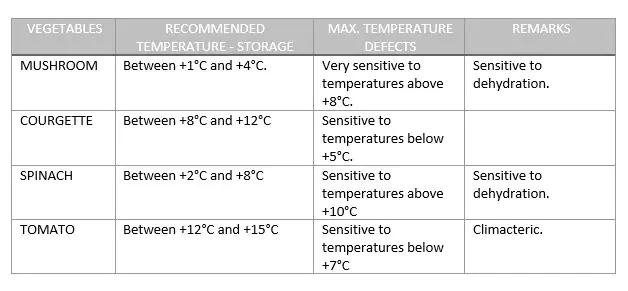

For guidance, here is a scale of storage temperatures for fruit and vegetables:

Temperature <0°C: risk of freezing. A vegetable that contains a lot of water will quickly crystallise. E.g. lettuce, which should never be allowed to come into contact with low-temperature container walls as there would be a risk of the leaves freezing and turning black;

Temperature between 0°C and +8°C: risk of disease due to cold;

Temperature between +8°C and +15°C: standard temperature range for storing fruit and vegetables;

Temperature between +18°C and +25°C: ideal temperature range for ripening;

Temperature above +28°C: risk of deterioration and damage to F&Vs;

Remember that in some cases there will be specificities due to origin of the fruit or vegetable (tropical origin, for example). Do not hesitate to contact our team for a personalised study.

By this we mean the moisture content in the air around the fruit and vegetables. On average, it is necessary to maintain the humidity of the air at around 80%. Warehouses are equipped with vaporising or nebulising humidifiers.

Fruit and vegetables give off heat and vegetables and ethylene, a plant hormone that accelerates their ripening. So to avoid peaks and homogenise the temperature, the air has to be renewed by ventilation.

Light is a decisive factor for all tuber and toot vegetables that mature underground in the dark. This is why we often see products wrapped in tissue paper to protect them from exposure to the light and therefore potential aging.

Using dedicated insulated containers is therefore a way of managing F&Vs according to their particular qualities and needs.

Finally, if there is no area specifically dedicated to the storage of fruit and vegetables at the warehouse or stores, a just-in-time logistics organisation is recommended.