1956

Creation of the companyThe founder, Jean OLIVO, was fascinated by the moulding of the new plastic materials

We live in a world where people are the key.

Pascal Sénéclauze, Président of Olivo.

Our organisation, our teams and our know-how address tomorrow’s ecological, political and human challenges that will shape the industry of the future.

We design and make, in the Department of Loire, insulated solutions and passive cold sources for sober, low-carbon logistics that is contributing to the ecological transition of supply chains and meeting the need to pool flows, optimise loads and implement multimodality.

From the choice of our materials and production processes to the deployment of a logistics model that makes sense, we take a long view, always looking to the future.

40 men and women work day after day to develop Olivo’s expertise. It is their passion and commitment that have helped to develop the international reach of our Blue Factory.

Laboratory & design office

With our R&D department made up of a laboratory and a design office, we are able to meet the specific requirements of our customers’ applications and uses. Pre-qualification analyses, characterisation studies, accessorisation projects are just some of the services we offer as well as the products themselves.

As part of a continuous improvement-based approach, we design and make prototypes that anticipate market needs and provide new solutions for tomorrow’s logistics.

Showroom and customer space

Cultivating close relations with customers in friendly, welcoming facilities is essential to the creation of a winning customer experience. We see the customer pathway as a journey where the customer is listened to, supported, advised and able to get to know our products through demonstration. We firmly believe in proof by example and we strive to put that policy into practice on a daily basis.

Factory

In our factory efficiently organised into four areas focused on handling, manufacturing and storage, we currently produce 10,000 insulated containers and X eutectic plates a year. The factory operates on a 3-shift schedule ensuring operational continuity and faster turnaround times.

The factory is organised to meet the highest safety standards, and we are constantly improving performance thanks to two intertwined spheres of competence, quality and production.

10 000K

Euros

Sales achieved in 2022.

300 K

Euros

Budget invested in R&D in 2023. Operational innovation is at the heart of our DNA.

10 K

Containers

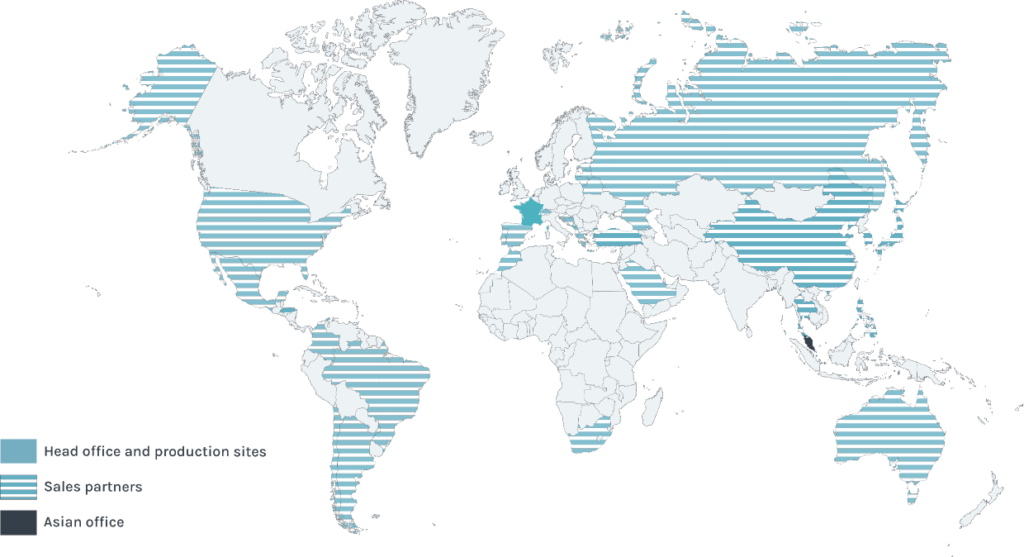

Every year we produce 10,000 containers that are exported to more than 100 countries around the world.

Do you need more information or a chat with our teams about a logistics project?

ZA Charles Chana

1 boulevard des Mineurs – CS 50019

42230 Roche-la-Molière

Tel : +33 (0)4 77 90 68 63