Temperature-controlled transport refers to the movement of temperature-sensitive goods using cold chain logistics solutions. It involves food, pharmaceutical, or cosmetic products that must be kept within specific temperature ranges:

- Positive temperature: fresh products (+0 to +4°C), certain cosmetics.

- Negative temperature: frozen products (–18°C).

- Specific controlled temperature: medicines (+2°C to +8°C or +15°C to +25°C).

The goal is to preserve the quality, sanitary safety, and organoleptic properties of sensitive products throughout the logistics chain, from production site to point of consumption. Even the slightest break in the cold chain can lead to product deterioration, health risks, regulatory non-compliance, or economic losses for the companies involved.

1. What are the current regulations?

Refrigerated transport law in France: What legal text governs the requirements for transporting foodstuffs?

Temperature-controlled transport is governed by both European regulations and French legislation. The main references are:

- Regulation (EC) No. 852/2004 on the hygiene of foodstuffs: requires the implementation of measures to ensure food safety at all stages, including transport.

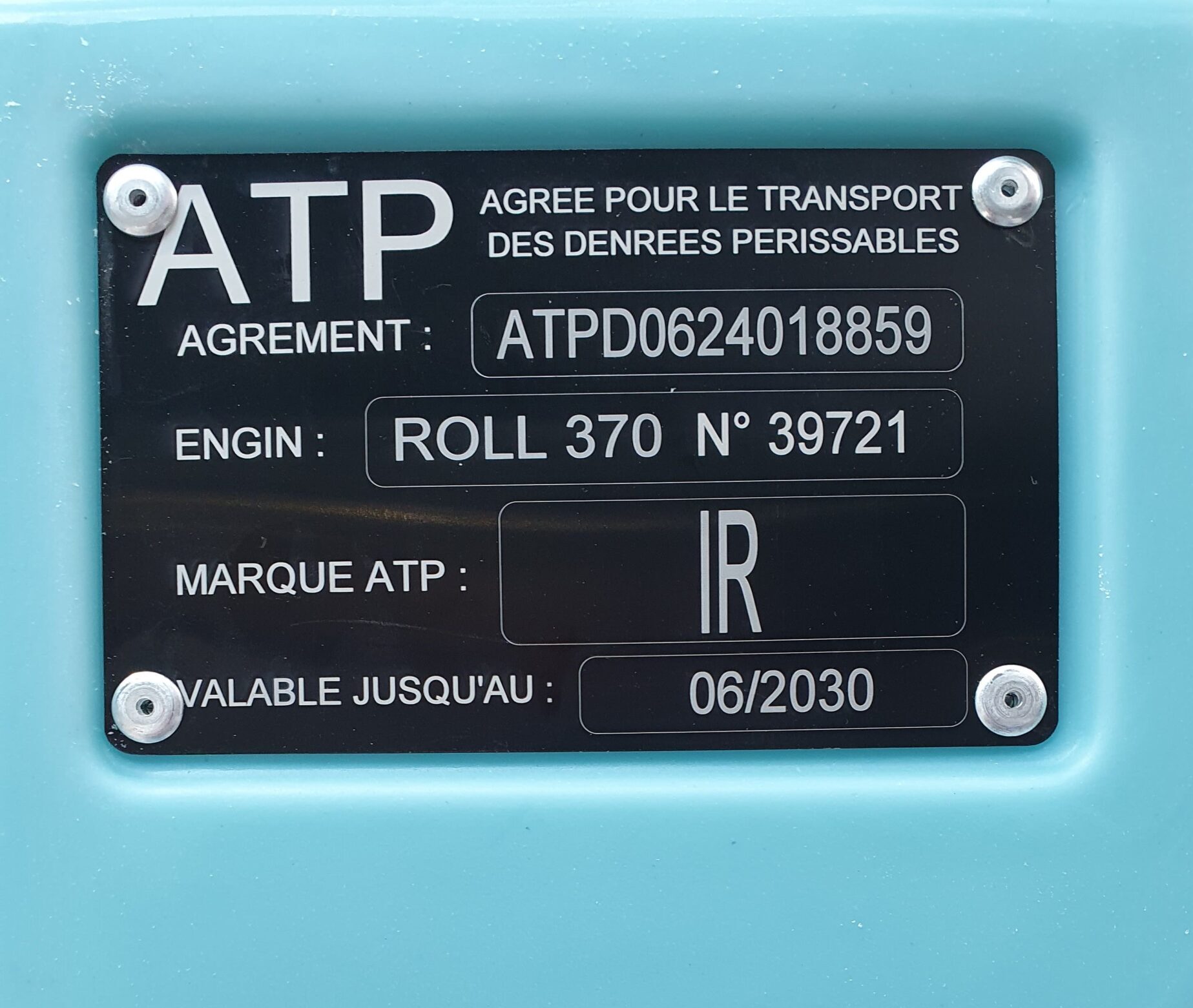

- ATP Agreement (Agreement on the International Carriage of Perishable Foodstuffs): imposes technical requirements for vehicles used (insulation, refrigeration unit, certification, etc.) in cross-border transport. It also applies in France for domestic transport.

- Rural and Maritime Fishing Code – Article R231-59: mandates compliance with regulated temperatures for products of animal origin, under penalty of sanctions.

- Decree of December 21, 2009: specifies the list of products subject to ATP regulation.

These legal texts govern practices in the cold chain logistics sector regarding temperature compliance, equipment, and traceability. Their purpose is to protect the end consumer by securing the transport of temperature-sensitive goods.

2. What are the obligations for professionals?

Mandatory equipment for refrigerated transport: What are the carrier’s obligations for temperature-controlled logistics?

Companies operating under temperature control must meet several technical and operational requirements:

- Use of ATP-approved vehicles: To transport temperature-sensitive goods, vehicles must comply with ATP standards. This approval, issued by an accredited technical center and valid for six years, certifies the vehicle’s ability to maintain a controlled temperature.

One key criterion is the isothermal performance of the container, measured by the thermal transmission coefficient (K). The lower the K value, the better the thermal insulation. The ATP defines two performance levels:

- K ≤ 0.7 W/m².K: for “normal insulation” (IN) equipment, for transporting fresh products.

- K ≤ 0.4 W/m².K: for “enhanced insulation” (IR) equipment, for transporting frozen products.

These thresholds qualify the effectiveness of the insulation in preserving temperature, ensuring optimal control of the cold chain—even under extreme weather conditions.

- Equipment suited to the transported goods: isothermal containers (such as those from Olivo), autonomous refrigeration units, cold accumulators, etc. The choice depends on transport duration, volume, type of goods, and logistical constraints (urban zones, last-mile delivery, etc.).

- Monitoring and traceability systems: Temperature tracking is essential. It is done using data loggers, connected probes, or IoT platforms. Any anomaly must be documented.

- Verification procedures: Carriers must check temperatures during loading and delivery, keep proof of compliance, and ensure full traceability of the transport.

- Staff training: Drivers and operators must be trained in best practices for cold chain management, use of refrigeration equipment, and basic hygiene regulations.

The carrier’s responsibility is engaged at every stage of the process. Any undetected or poorly documented temperature breach can lead to product destruction and regulatory penalties.

3. What specific conditions must be known for transporting sensitive products?

Transport temperature for frozen products

Frozen products must be transported at –18°C. A temporary tolerance up to –15°C is allowed during logistical phases such as loading or unloading. However, the average temperature throughout the transport must remain at –18°C.

Respecting these thresholds is crucial, as a rise in temperature can cause the reformation of ice crystals, texture loss, and microbiological degradation of the products.

Medicine transport

The transport of healthcare products is governed by the Good Distribution Practices (GDP) issued by the French National Agency for the Safety of Medicines (ANSM). Requirements vary depending on the nature of the medicine:

- Temperature-sensitive medicines: controlled temperature between +2°C and +8°C.

- Standard medicines: stored between +15°C and +25°C.

Obligations include:

- Strict adherence to the temperature range indicated by the manufacturer.

- Use of certified isothermal containers.

- Recording and archiving of all temperature data.

- Real-time alerts in case of deviation.

- Equipment qualification (temperature hold tests).

- Training of transport and logistics personnel.

Contact our sales team today for a free assessment and discover how to optimize your cold chain while controlling your costs.

How does cold chain logistics involve stakeholder responsibility?

Temperature-controlled transport in France relies on a fundamental triptych: regulations, responsibility, and rigor.

For transporters, distributors, or laboratories, it’s not just about delivering products—it’s about ensuring their quality, safety, and regulatory compliance.

Our news in cold logistics

View the blog

-

Mass cold transport : being profitable, responsive and secure

18 November 2025

by Edina GÁLFI

-

The 3 key tips to prevent temperature excursions during transport

16 September 2025

by Edina GÁLFI

-

What are the standards, requirements, and logistics solutions for frozen product transportation?

16 July 2025

by Edina GÁLFI