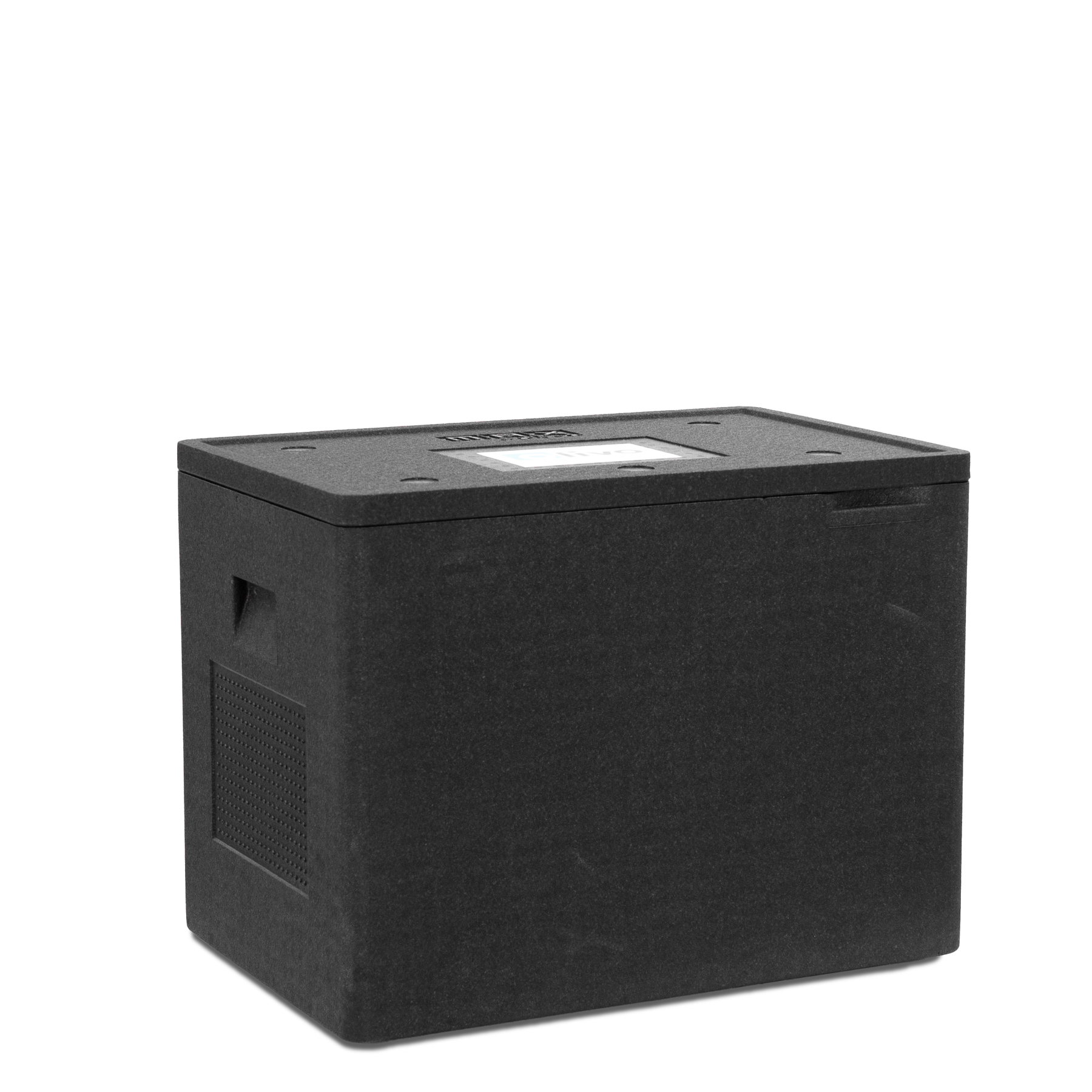

Ext. dim. : 595 x 395 x 455 mm,

Volume : 60 L,

Cold source : eutectic plate TOP 64,

Logistics format : Quarter Euro-pallet 800 x 1200

View detailsSustainable, professional-quality insulated boxes, perfect for transporting chill or frozen food products. Suitable for professionals in the food trade (caterers, restaurants, delicatessens, etc.) who want to develop a home delivery service.

Olivo products are 100% made in France

2 results

Ext. dim. : 595 x 395 x 455 mm,

Volume : 60 L,

Cold source : eutectic plate TOP 64,

Logistics format : Quarter Euro-pallet 800 x 1200

View details

Ext. dim. : 555 x 360 x 331 mm,

Volume : 34 L,

Cold sources : eutectic plate TOP 64 et SiberCity®,

View detailsOlivo specialises in the manufacture of isothermal containers and passive cooling systems.

Transport your heat-sensitive products in complete safety with an isothermal box that will keep them at the target temperature while you make your deliveries. Our isothermal boxes and BACs have been designed to provide you with excellent temperature maintenance thanks to various solutions developed by our Research and Development department: dual-temperature cryogenic refrigeration, eutectic solutions, cryogenic refrigeration for last-mile logistics in fresh and frozen products, etc.

The BOX range consists of isothermal boxes for small-volume transport that can be described as isothermal packaging or refrigerated crates.

BOX insulated packaging is designed primarily for last-mile logistics.

OLIVO isothermal BOXes are reusable refrigerated / isothermal boxes designed for transport by logistics professionals delivering directly to the consumer.

Interested in our insulated containers? Contact us

Robust, one-piece, stackable, reusable and recyclable, they are ideal for transporting perishable goods over the last kilometre.

More than just an isothermal box, this is a technology designed by experts in the cold chain and logistics. Depending on your logistics issues, our experts will help you choose the model best suited to your logistics circuit and organisation. Their aim: to help you improve efficiency and profitability while guaranteeing the safety of your products.

Isothermal refrigerated boxes dedicated to last-mile delivery professionals: e-commerce, home delivery, short routes and urban logistics.

Ergonomic, recyclable, strong, ultra-light and stackable, OLIVO's isothermal solutions combined with eutectic plates (autonomous passive cold source) or cryogenic cold enable you to maintain the temperature of your products for up to 16 hours.

Compatible with conveyor crates and designed to optimise your logistics, OLIVO's expanded polypropylene solutions have been designed to transport perishable goods in complete safety.

Do you want to develop home deliveries and have minimum volumes of 300 boxes per day? OLIVO has developed a patented cryogenic solution, MINICRYO®, for transporting fresh and frozen products.

Adapted to the development of optimised and automated logistics to ensure a reduction in your costs.

BOX isothermal refrigerated boxes are a real concentrate of ergonomics and thermal expertise:

In response to direct-to-consumer delivery, OLIVO sought to adapt its temperature maintenance system to isothermal boxes specifically designed for the last mile.

For the solution to be effective and provide satisfaction for our customers, we had to find the cold container that would provide the right thermal result while being as light and space-saving as possible.

Our approach was therefore ergonomic: to design cold packs capable of maintaining the temperature of foodstuffs and which could be used with maximum efficiency, safety and comfort.

The weight and size of the isothermal BOX are important criteria here:

smaller delivery vehicles ; electric vehicles; hand-carrying in the case of home delivery;

OLIVO insulated boxes maintain the temperature of thermally sensitive products at positive or negative temperatures. Dry products that do not require thermal protection can be packed in plastic crates.

The number of deliveries is increasing and the size of packages is decreasing. BOX isothermal boxes are the perfect solution for preparing e-commerce orders in plastic crates.

PPE material

OLIVO has chosen a fantastic material for its isothermal BOX range: expanded polypropylene, commonly known as PPE.

PPE is a polypropylene foam made up of closed cells. It is 100% recyclable and its production uses steam. PPE is therefore a "green" material that respects the environment.

Don't be fooled: visually, EPP looks like expanded polystyrene, but the material is completely different.

PPE is renowned for its strength and lightness, but it also has many other qualities:

BOX isothermal boxes are moulded in one piece from PPE. A single material therefore ensures the rigidity of the box and its isothermal properties.

The thickness of the walls of BOX insulated packaging is between 30 and 35 mm in order to achieve the required thermal performance. The thickness of the insulation is the result of a compromise that satisfies the thermal performance/space requirements.

Reducing the thickness of the insulation is an attractive way of transporting more products in the same space, but by reducing the level of isotherm, temperature maintenance will be shorter or require greater consumption of refrigeration.

Cooling BOX isothermal boxes with eutectic plates enables a positive (fresh produce) or negative (frozen food) temperature to be maintained for 12 hours or more.

For different transport environments (summer, winter, mid-season), you know exactly how many eutectic plates need to be placed in the isothermal BOX for the desired shelf life.

The latest isothermal box models can hold up to 9 eutectic cartridges in special grooves.

This modular use of refrigeration packs is a highly reliable and easy-to-manage method.

Placing solid dry ice in the isothermal transport box is only suitable for transporting frozen foods.

In this case, the lid of the isothermal transport box can be fitted with a net to hold the dry ice pack.

OLIVO calculates the amount of dry ice you need for the expected duration.

Using OLIVO's experience and that of its partner MESSER to miniaturise the "on-demand" production of the SIBER SYSTEM® cryogenic system for small BOX-type containers: a successful challenge that is revolutionising last-mile logistics for fresh and frozen products.