Dry Ice Delivery: How to Combine Refrigerated Transport Optimization and Compliance with Safety Standards?

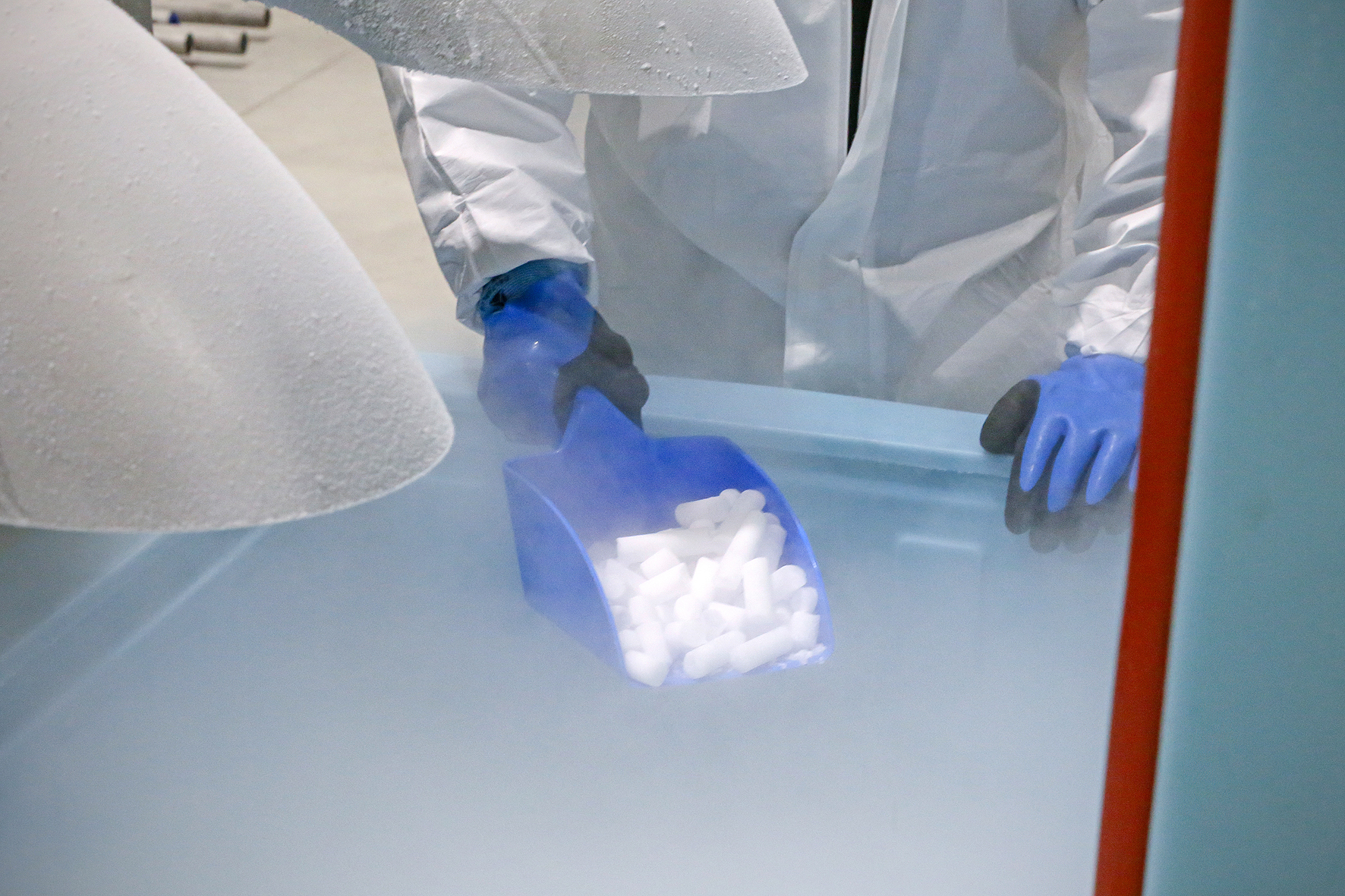

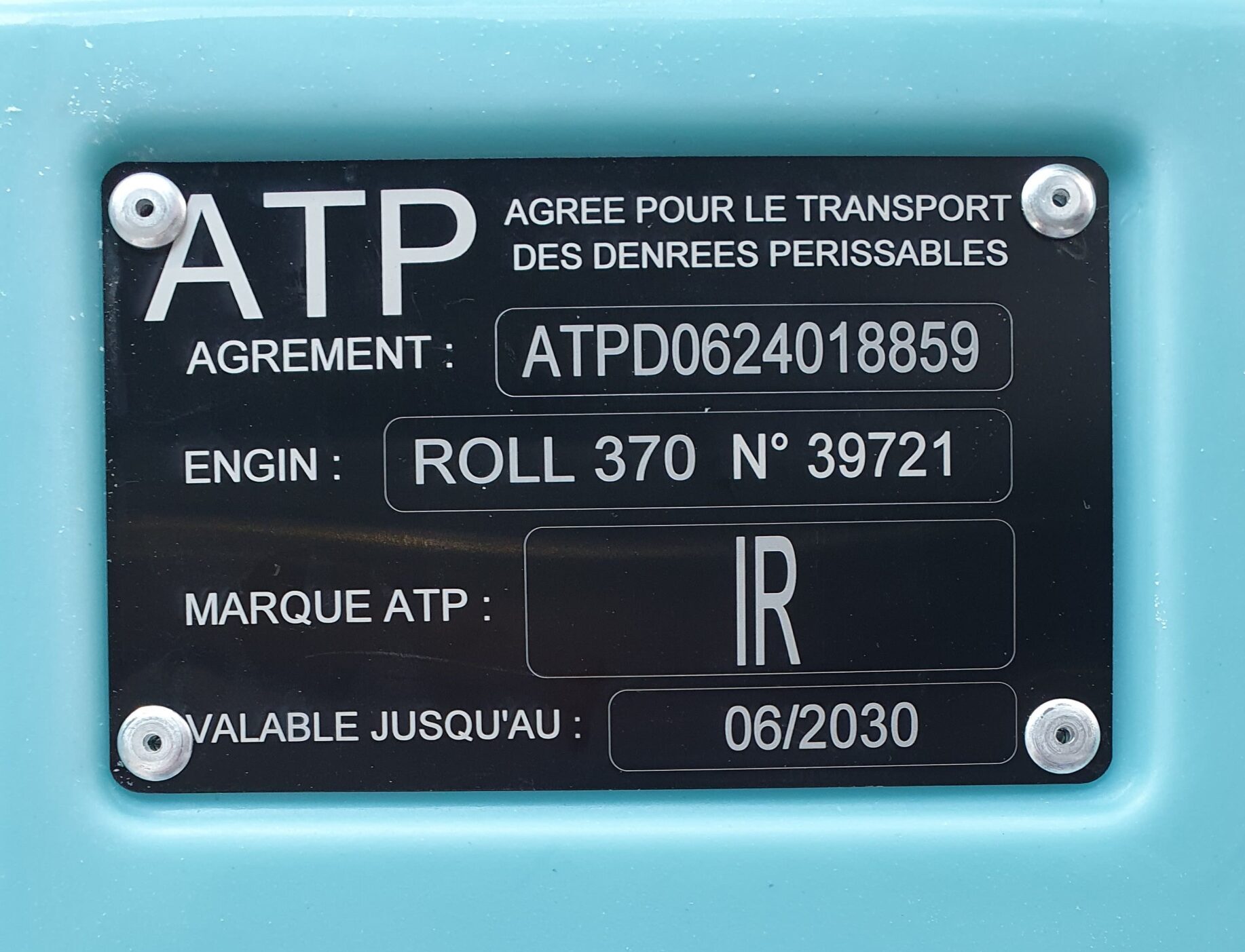

Transporting refrigerated and frozen products is a major challenge for many industries, particularly those handling foodstuffs, pharmaceuticals, or temperature-sensitive equipment. Among the solutions used to maintain an adequate temperature is dry ice. Its use requires a good understanding of its characteristics, the safety rules related to its transport, as well as best practices for handling and storage.

18 June 2025